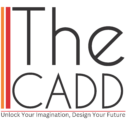

PowerMill Course

What's in this course?

Autodesk PowerMill is a powerful software solution for complex and high-speed machining applications. It offers a wide range of operations to optimize the manufacturing process. Here’s a list of key operations available in Autodesk PowerMill:

1. Roughing Operations:

- Area Clearance: Removes large volumes of material efficiently using various strategies such as offset, raster, and adaptive roughing.

- Rest Roughing: Targets material left from previous roughing operations to ensure efficient material removal.

2. Semi-Finishing Operations:

- Rib Machining: Specialized for removing material from rib-like features in molds and dies.

- Offset Area Clearance: Prepares the part for finishing by following the contour of the surface.

3. Finishing Operations:

- Raster Finishing: Uses parallel passes to produce high-quality surface finishes on complex 3D surfaces.

- 3D Offset Finishing: Follows the shape of the model for consistent surface finish.

- Spiral Finishing: Generates continuous spiral tool paths for smooth surface finishes.

- Flowline Finishing: Follows the natural flow of the surface for a superior finish.

4. High-Speed Machining Operations:

- Trochoidal Milling: Reduces tool wear and enhances efficiency in high-speed cutting conditions.

- Adaptive Clearing: Adapts to material conditions dynamically for optimal cutting performance.

5. Rest Finishing Operations:

- Rest Finishing: Targets residual material left from previous finishing operations for a cleaner finish.

6. Feature-Based Machining:

- Hole Drilling: Automated drilling cycles for different hole types and patterns.

- Feature Recognition: Automatically identifies features such as pockets, slots, and bosses for efficient machining.

7. 5th Axis Machining Operations:

- Swarf Cutting: Utilizes the side of the tool to cut along the surface.

- 3+2 Machining: Locks the tool at a fixed angle for complex 3D cutting.

- Simultaneous 5-Axis Machining: Enables full 5-axis movement for complex geometries.

8. Toolpath Verification and Simulation:

- Toolpath Simulation: Visually verify toolpaths to detect collisions and errors before actual machining.

- Material Removal Simulation: Simulates the material removal process to ensure optimal toolpath strategy.

9. Customization and Automation:

- Scripting and Macros: Automate repetitive tasks and customize workflows using PowerMill’s scripting capabilities.

- Toolpath Templates: Create and reuse toolpath templates for consistent and efficient programming.

10. Optimization and Analysis:

- Toolpath Optimization: Adjust toolpaths for improved efficiency and reduced machining time.

- Feedrate Optimization: Dynamically adjusts feed rates based on cutting conditions to enhance tool life and performance.

11. Collaboration and Data Management:

- NC Program Management: Organize and manage NC programs for efficient workflow.

- Cloud Collaboration: Share and collaborate on projects with team members using cloud services.

By leveraging these operations, users of Autodesk PowerMill can achieve high precision, efficiency, and quality in their manufacturing processes.

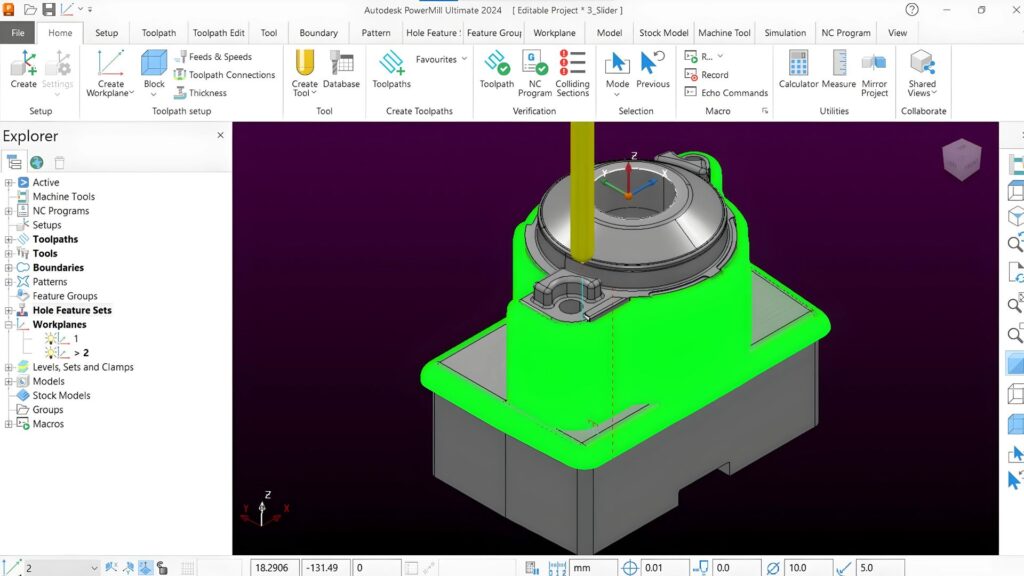

Who can benefit from PowerMill?

Are you looking to improve your manufacturing processes and reduce production times? Whether you’re a small business owner or part of a large corporation, Autodesk PowerMill can help streamline your operations and improve your bottom line. Our software is used in industries such as aerospace, automotive, and medical devices to create complex and high-precision parts. With PowerMill, you can optimize your machining and toolpath strategies, simulate and verify your designs, and collaborate seamlessly with your team. Don’t let outdated manufacturing practices hold you back. Unlock your imagination and design your future with PowerMill.